Dsigns and Manufactures.

Octagonal Poles, Conical Poles & Tubular Poles for highway, street lighting and traffic signals. Our product value chain begins with the procurement of hot rolled coils, confirming to international standards and grade of steel as per project requirement which are then used as in puts for the manufacture of poles.

CNC Flame Cutting Process

We have Portable CNC Flame Cutting machine to cut the base plate for the poles precisely. We program to machine as per required dimensions to cut them at erial automatically with accuracy.

De-Coiler Process

De-Colier uses to hang the sheet coil to open the sheet turns from coil, which can insert in to straighter to make the sheet straight.

Sheet Straightner

Sheet Straightner uses to make the sheet straight before slitting / sheering the sheet. Straighter having capacity to straight the sheet up to 8mm thick.

Slitting Machine

After Straightening the sheet its cut as per required length of pole. This cut piece of sheet then slitted in two halves longitudinally in slitting machine.

CNC Tandem Hydraulic Press Brake

A CNC 54' press brake forms the longitudinal bends that shape the multi-sided tapered pole. Mounting height of pole is between 5 meter to 15 meter and thickness capacity to is between 2.5mm to 8mm.

Sub-Merged Arc Welding Machine

A CNC 54' press brake forms the longitudinal bends that shape the multi-sided tapered pole. Mounting height of pole is between 5 meter to 15 meter and thickness capacity to is between 2.5mm to 8mm.

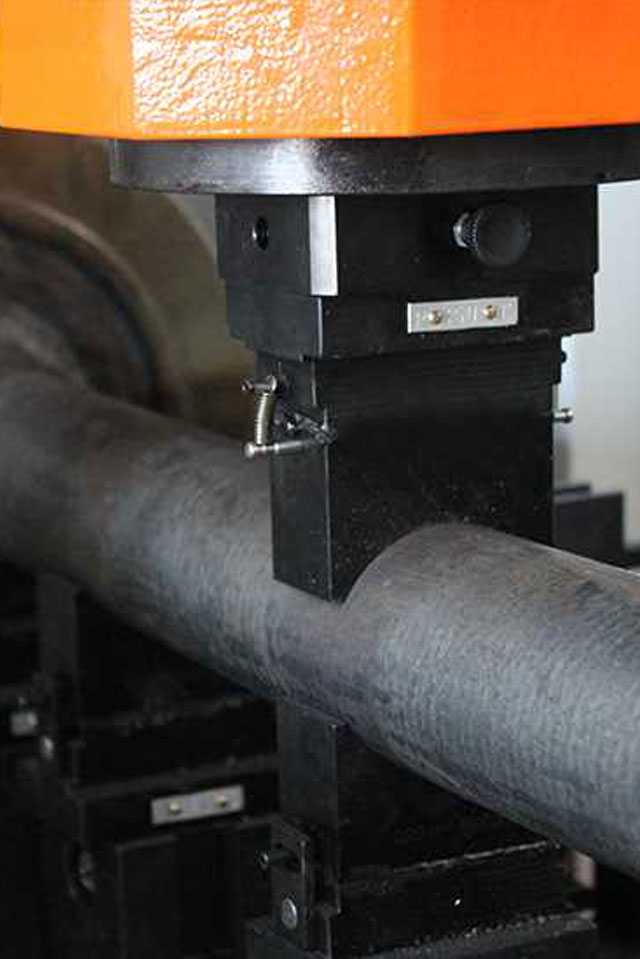

Shaft Straightening Press

After one side welding longitudinally, shafts get distorted so we use the hydraulic press to make it straight and align with axis.

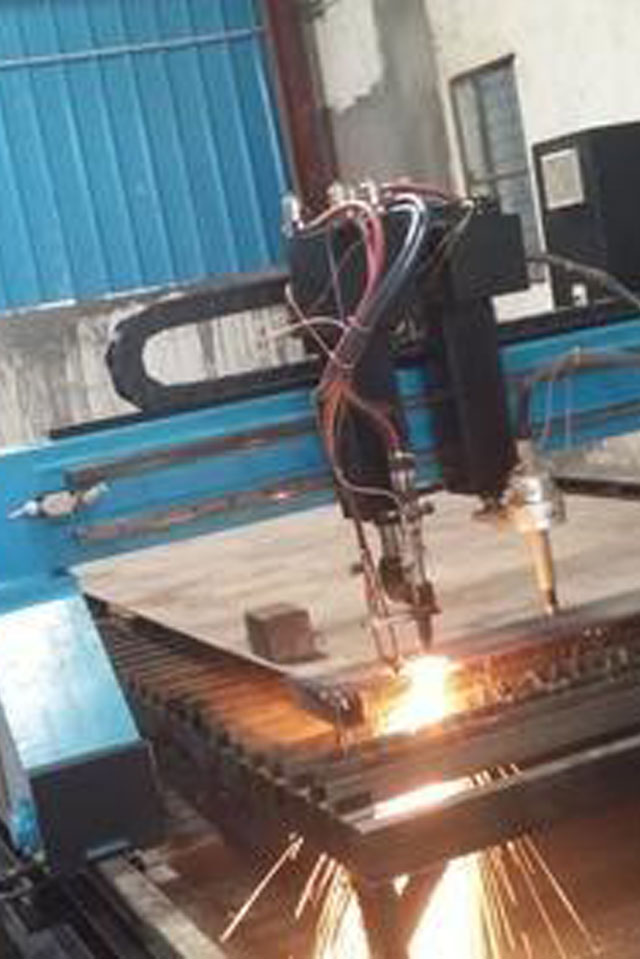

Portable CNC Plasma Machine

CNC Plasm machine used to cut window on the bottom of pole for electrical connections to the light. We program to machine for cutting window accurately as per project requirements.

Co 2 Welding on Base Plates

Base Plate of pole welded by qualified welders byusing Co2 welding plant and Electric Arc welding plant.